Guide to Choosing Automatic Screwdrivers: Key Factors for High-Volume Production Lines | Essential Selection Guide for Smart Screw Machines

| Product Name | Applicable industries |

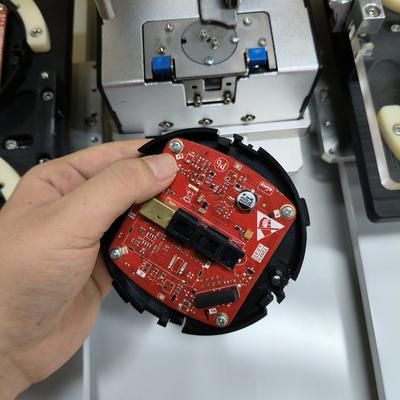

| Smart Screw Driving Machine | Automotive Electronics Assembly |

Choosing the Right Auto Screw Driver: Essential Factors for High-Volume Success

High-volume production lines demand more than just speed. They require relentless reliability, precision, and efficiency to hit aggressive targets consistently. Choosing the wrong automated screwdriver for these demanding environments can become a significant bottleneck, leading to frustrating downtime, costly errors, and eroded profitability. Selecting the optimal tool involves evaluating several critical performance factors beyond the basic specification sheet.

1. Precision Torque Control & Repeatability: The Non-Negotiable Foundation

Inconsistent torque is the root cause of numerous assembly headaches – from loose connections causing product failures and recalls, to overtightening damaging delicate components or stripping threads. The ideal system must offer:

- Closed-Loop Torque Feedback: Continuously monitors and adjusts the applied force in real-time to match the exact programmed target.

- Exceptional Repeatability: Consistently achieves torque values within a very tight tolerance window (e.g., ±3% of target), thousands of times per shift, ensuring every screw meets the quality standard.

- Multi-Stage Programming: Allows setting distinct phases (seating, driving, tightening) with different speeds and torque levels, optimizing the process and preventing cam-out or damage.

2. Unwavering Speed & Cycle Time Optimization

Seconds saved per screw compound rapidly in high-volume settings. Look for:

- High RPM Capability: Powerful brushless motors capable of high rotational speeds without sacrificing torque output.

- Rapid Pick-Up & Reaction Time: Swift engagement once the driver tip detects the screw head or receives the start signal. Minimal lag is crucial.

- Optimized Retraction Speed: Fast but controlled movement away after tightening to minimize wasted motion.

3. Robust Durability & Minimal Maintenance

Constant operation inevitably causes wear. The best drivers are engineered for endurance:

- Premium Construction: Industrial-grade housings and internal components designed to withstand vibrations, impacts, and millions of cycles.

- Brushless Motor Advantage: Longer lifespan, higher efficiency, less maintenance, and no carbon brush replacement compared to brushed motors.

- Effective Dust/Contaminant Resistance: Protection against ingress of oils, metal shavings, and debris common in manufacturing environments.

- Modular Design: Simplifies servicing; key consumables (like clutches or spindles) can be replaced quickly and affordably with minimal downtime.

4. Operator Ergonomics (If Manual Intervention is Involved)

Even in automated cells, manual stations exist. Poor ergonomics lead to fatigue, RSI, and reduced output:

- Lightweight Design: Reduces operator strain over long shifts.

- Balanced Weight Distribution & Comfort Grip: Encourages natural posture and reduces pressure points.

- Low Vibration Design: Absorbed vibration protects operator health and improves control.

- Kink-Resistant Hoses/Cables: Minimizes drag and tangles, improving maneuverability.

5. Advanced Features for Seamless Integration & Control

For complete assembly line intelligence:

- Integrated I/O & Network Communication: Easily connects to PLCs, HMIs, MES, or SCADA systems for process monitoring, data collection (tracking torque, angle, cycles), and remote control. Standards like EtherCAT, PROFINET, Ethernet/IP can be essential.

- Tool Presence & Step Detection: Ensures the driver is correctly positioned on the screw head before starting and can map operation stages.

- Angle Monitoring: Verifies screw rotation, essential for thread-forming applications or confirming engagement.

- Electronic Feeder Compatibility: Faultless integration with screw presentation systems via standardized interfaces for high-speed, reliable feeding.

- Data Logging & Traceability: Stores detailed process data per fastening point, crucial for quality audits and defect analysis.

The "best" driver isn't about a single model; it's about identifying the perfect combination of proven features matching your specific high-volume requirements. Prioritize exceptional torque accuracy and repeatability – the bedrock of assembly quality. Demand blistering speed delivered by robust and durable brushless motor technology. Ensure the system is designed for continuous operation with minimal unscheduled maintenance.

For operators, prioritize ergonomics that sustain productivity. Most importantly, choose a driver built for modern Industry 4.0 lines, offering full connectivity, real-time process control, and comprehensive data collection for complete transparency and traceability. By prioritizing these critical performance characteristics over features less relevant to your operation, you guarantee smooth high-volume production backed by predictable uptime and uncompromising quality.