Reducing Rework Rates with Precision Feeding Systems | Manufacturing Efficiency

Reducing Rework Rates with Precision Feeding

In today's competitive manufacturing landscape, reducing rework rates is critical for maintaining efficiency, cutting costs, and ensuring product quality. One of the most effective strategies to achieve this is through precision feeding systems. These advanced solutions minimize errors in material handling and assembly processes, significantly lowering the chances of defects that lead to rework.

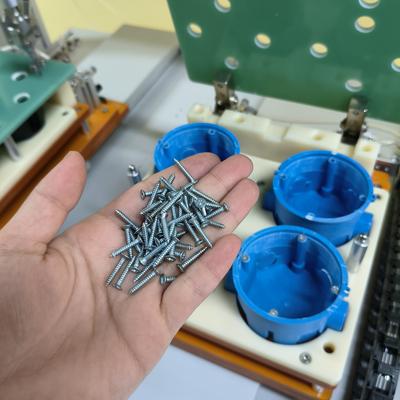

Precision feeding involves the accurate and consistent delivery of components or materials to assembly lines or processing stations. By leveraging advanced sensors, automation controllers, and real-time monitoring, these systems ensure that every part is positioned correctly before subsequent operations. This eliminates misalignment, incorrect part placement, and other common issues that degrade production quality.

Key benefits of precision feeding include:

- Reduced Waste: Fewer defective products mean less material waste and lower disposal costs.

- Improved Efficiency: Consistent part placement reduces downtime caused by manual corrections.

- Higher Throughput: Automated precision feeding ensures faster cycle times without compromising quality.

- Enhanced Traceability: Integrated monitoring tracks feeding accuracy for continuous improvement.

Industries such as automotive, electronics, and packaging have seen remarkable improvements by adopting these systems. For example, a slight deviation in component positioning during circuit board assembly can lead to faulty connections, requiring costly rework. Precision feeding eliminates such issues by ensuring exact placement every time.

Modern precision feeding solutions are also highly adaptable. They can be customized for different part geometries and integrated with smart manufacturing systems to further optimize performance. Machine learning algorithms can even predict and adjust feeding parameters dynamically, reducing the risk of errors before they occur.

Investing in precision feeding technology not only lowers rework rates but also enhances overall production reliability. As manufacturers strive for zero-defect processes, these systems will play an increasingly vital role in meeting quality and efficiency targets.

To implement precision feeding effectively, companies should evaluate their current processes, identify error-prone stages, and select systems that align with their operational needs. The long-term savings in rework costs and productivity gains make this a worthwhile investment for any forward-thinking manufacturer.

| Product Name | Applicable industries |

| Automatic Screw Feeder | LED Lighting Industry |