Automated Screw Locking Machine | Boost Assembly Line Efficiency

How an Automated Screw Locking Machine Enhances Assembly Line Efficiency

In today’s competitive manufacturing landscape, maximizing efficiency while maintaining precision is a top priority for businesses. One innovation that has revolutionized assembly processes is the automated screw locking machine. Designed to streamline production workflows, this technology eliminates bottlenecks, reduces human error, and ensures consistent output. Let’s explore how integrating this equipment can transform your assembly line operations.

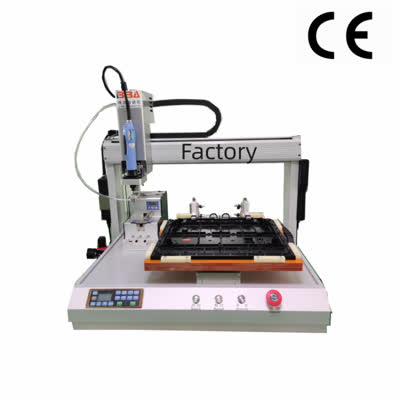

Key Features of Automated Screw Locking Systems

Modern automated screw locking machines incorporate advanced technologies to deliver unparalleled performance. Equipped with precision-guided electric screwdrivers, these systems can handle screws of varying sizes and materials. Built-in sensors detect screw placement in real time, adjusting torque and alignment automatically to prevent cross-threading or overtightening. Additionally, multi-axis robotic arms enable 360-degree access to assembly components, ensuring screws are secured even in hard-to-reach areas.

Boosting Productivity Through Speed and Consistency

Manual screw fastening is time-consuming and prone to variability. An automated system, however, operates at a fixed cycle time, enabling up to 30% faster production rates. By eliminating pauses for operator fatigue or tool adjustments, assembly lines achieve continuous operation. Moreover, automated torque control guarantees every screw meets exact specifications, reducing rework rates and minimizing material waste.

Reducing Labor Costs and Workplace Strain

Repetitive screw-driving tasks can lead to worker fatigue and musculoskeletal injuries, resulting in higher absenteeism and healthcare costs. Automating this process reduces reliance on manual labor, allowing employees to focus on higher-value tasks such as quality inspection or machine oversight. This not only improves workplace safety but also lowers long-term operational expenses.

Seamless Integration with Smart Manufacturing

Next-generation screw locking machines are IoT-enabled, providing real-time data on production metrics, machine health, and maintenance needs. Integration with Manufacturing Execution Systems (MES) allows supervisors to monitor screw fastening accuracy, track throughput, and identify inefficiencies. Predictive maintenance algorithms further reduce downtime by alerting teams to potential issues before they escalate.

Applications Across Industries

From automotive manufacturing to consumer electronics, automated screw locking systems cater to diverse sectors. In automotive assembly, these machines ensure critical components like engines and dashboard panels are securely fastened. For electronics, they enable delicate screw placement on circuit boards without damaging sensitive parts. Customizable configurations make them adaptable to high-mix, low-volume production runs as well as mass-scale operations.

ROI and Long-Term Benefits

While the initial investment in automated screw locking equipment may seem significant, the long-term payoff is substantial. Increased throughput, reduced defect rates, and lower labor expenses typically lead to a ROI within 12–18 months. Furthermore, the scalability of these systems ensures they remain viable as production demands grow.

Conclusion

Adopting an automated screw locking machine is a strategic move for manufacturers aiming to optimize their assembly lines. By enhancing speed, precision, and operational safety, this technology not only drives productivity but also strengthens competitiveness in an increasingly automated industry. As manufacturing evolves, integrating such solutions will be essential for businesses committed to sustainable growth and innovation.