Robotic Screw Driving Machines | Industrial Automation Export Solutions

The global manufacturing landscape is undergoing a significant transformation, driven by the increasing demand for efficiency, precision, and cost-effectiveness. In this context, robotic screw driving machines have emerged as a pivotal technology, offering substantial export opportunities for industrial automation product companies. These machines, which automate the traditionally manual and repetitive task of screw driving, are gaining traction across various industries worldwide.

One of the primary factors fueling the export potential of robotic screw driving machines is the widespread adoption of automation in developed and emerging economies. Countries with strong manufacturing sectors, such as Germany, Japan, the United States, and China, are continuously seeking to enhance their production capabilities. Robotic screw driving machines provide a solution that not only improves assembly speed but also ensures consistent quality, reducing the risk of human error. This reliability is particularly valuable in industries like automotive, electronics, and aerospace, where precision is paramount.

Moreover, the growing emphasis on lean manufacturing and just-in-time production methods has created a robust demand for flexible automation solutions. Robotic screw driving machines can be easily integrated into existing production lines and programmed to handle multiple tasks, making them ideal for dynamic manufacturing environments. This adaptability allows exporters to cater to a diverse range of clients, from large-scale automotive manufacturers to small and medium-sized enterprises (SMEs) looking to optimize their operations.

Another key driver of export opportunities is the rising labor costs in many traditional manufacturing hubs. As wages increase, companies are increasingly turning to automation to maintain competitiveness. Robotic screw driving machines offer a compelling return on investment by reducing labor costs, minimizing assembly errors, and increasing throughput. This economic advantage makes them an attractive option for manufacturers in regions experiencing labor shortages or high labor expenses.

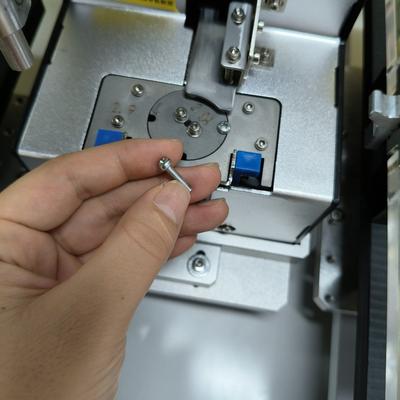

In addition to economic factors, technological advancements are expanding the capabilities and applications of robotic screw driving machines. Modern systems are equipped with advanced features such as vision systems, torque sensing, and AI-driven adaptability, allowing them to handle complex and delicate tasks with ease. These innovations open up new markets and applications, particularly in high-tech industries like consumer electronics, medical device manufacturing, and renewable energy.

To capitalize on these export opportunities, it is essential to understand the specific needs and regulations of target markets. Customization, reliable after-sales support, and compliance with international standards are critical factors for success. By offering tailored solutions and building strong relationships with distributors and end-users, companies can establish a strong global presence and drive the adoption of robotic screw driving machines worldwide.

In conclusion, the export potential for robotic screw driving machines is vast and continues to grow as industries worldwide embrace automation. By leveraging technological innovations, addressing market-specific requirements, and highlighting the economic and operational benefits, industrial automation product companies can tap into this lucrative market and contribute to the future of manufacturing.

| Product Name | Applicable industries |

| Inline Screw Locking System | Power Tool Assembly Lines |