Real-Time Tightening Parameter Monitoring | Industrial Assembly Quality Control

| Product Name | Applicable industries |

| Servo Screwdriver Robot | PCB and Circuit Board Assembly |

Real-Time Monitoring of Tightening Parameters

In the world of industrial manufacturing, the integrity of every threaded joint is paramount. A single loose bolt or over-torqued screw can lead to product failure, safety hazards, and costly recalls. This is where the real-time monitoring of tightening parameters transitions from a advanced feature to an absolute necessity for modern assembly operations. It represents a fundamental shift from reactive quality control to proactive process assurance.

What is Real-Time Monitoring?

Real-time monitoring is the continuous acquisition and instantaneous analysis of data during the fastening process. Unlike traditional methods that might only record the final torque value, a sophisticated real-time system captures a rich dataset throughout the entire tightening cycle. This includes key parameters such as:

- Torque: The rotational force applied to the fastener, measured continuously.

- Angle: The precise rotation of the tool from the start of the process, critical for yield-controlled strategies.

- Speed: The rotational velocity of the tool, which can impact the consistency of the joint.

- Time: The duration of the tightening cycle, identifying potential stalls or irregularities.

By analyzing the relationship between these parameters in real-time—visualized as a torque-angle curve—the system can make immediate judgments on joint quality.

The Critical Advantages of Instantaneous Data Analysis

The power of real-time monitoring lies in its ability to make decisions at the moment of assembly. This provides several transformative benefits:

100% In-Process Quality Control: Every single joint is verified as it is made. The system can immediately classify a fastening operation as "OK" or "NOK" (Not OK) based on predefined tolerance windows for the torque-angle signature. This eliminates the need for costly and time-consuming offline audits and prevents defective products from moving down the line.

Immediate Error Detection and Prevention: Real-time systems can identify and flag errors as they occur. Common issues like cross-threading, missing washers, hardened thread-locking compound, or worn-out taps are detected instantly by their unique signature on the torque-angle curve. The operator can be alerted immediately, stopping the production of faulty assemblies.

Process Optimization and Traceability: The vast amount of data collected provides unparalleled insight into the assembly process. Engineers can analyze trends to optimize tightening strategies, perform predictive maintenance on tools before they drift out of calibration, and identify potential wear in components. Furthermore, every critical joint can be traced with a complete data record, essential for audibility and compliance in industries like aerospace and automotive.

Real-time monitoring is not just about collecting data; it's about creating a closed-loop system where the assembly process is self-correcting and self-verifying, ensuring unparalleled consistency and reliability.

Key Features of an Advanced Monitoring System

To effectively implement real-time monitoring, the underlying system must be robust and intelligent. Key features include:

- High-Sampling Data Acquisition: Capturing data at a high frequency is essential to accurately reconstruct the torque-angle curve and identify subtle defects that low-frequency sampling would miss.

- Powerful Data Processing Algorithms: The system must process the incoming data stream with sophisticated algorithms to compare the live curve against the master reference curve and make a pass/fail decision within milliseconds.

- Instantaneous Feedback Mechanisms: The result of the analysis must be communicated instantly via visual signals (e.g., colored lights on the tool), audible alarms, or electronic signals to the PLC to stop the line if necessary.

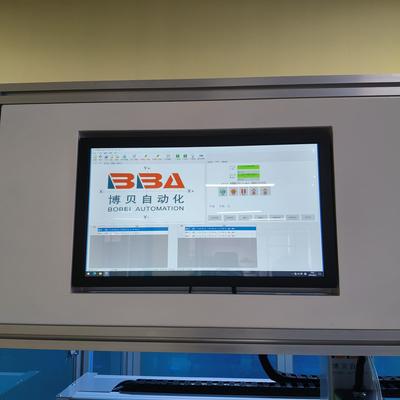

- Seamless Integration: The system must integrate effortlessly with existing production line PLCs, MES (Manufacturing Execution Systems), and database software for data logging and analysis.

Conclusion: The Future of Assembly is Connected and Intelligent

The adoption of real-time monitoring of tightening parameters is a definitive step towards the smart factory. It moves quality assurance from the end of the line directly to the point of assembly, empowering manufacturers with unprecedented control over their processes. The result is a dramatic reduction in costly errors, a significant increase in overall equipment effectiveness (OEE), and the production of safer, more reliable products. As Industry 4.0 continues to evolve, this level of data-driven intelligence will become the standard, not the exception, for any manufacturer serious about quality and efficiency.