Industrial Screw Locking Equipment Vendor Selection Guide | Expert Tips

| Product Name | Applicable industries |

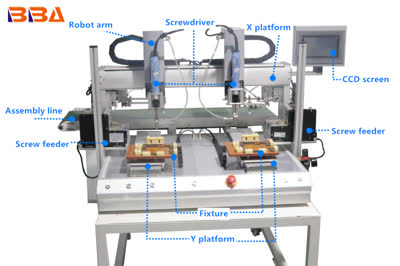

| Desktop Screwdriver Robot | Industrial Control Panel Assembly |

Vendor Selection for Screw Locking Equipment

Selecting the right vendor for screw locking equipment is a critical decision that can significantly impact your production efficiency, product quality, and overall operational costs. In today's competitive industrial automation landscape, the tools used for fastening and assembly are not just simple devices; they are sophisticated systems that require precision, reliability, and seamless integration into existing production lines. Therefore, a meticulous and well-informed vendor selection process is paramount for any manufacturing operation aiming for excellence.

The first step in this journey is to clearly define your technical requirements. Understand the specific needs of your application: the types of screws you use, the required torque and angle accuracy, the desired speed of operation, and the level of data tracking and connectivity needed. Will the equipment be used for high-volume, repetitive tasks, or for more complex, low-volume assemblies? Answering these questions will help you create a detailed specification list, which serves as the foundation for evaluating potential suppliers. This clarity ensures you only consider vendors whose equipment is technically capable of meeting your production demands.

Beyond the technical specifications, the quality and durability of the equipment are non-negotiable. Industrial environments are demanding, with constant use, vibration, and potential exposure to contaminants. Inquire about the materials used in the construction of the tools, the quality of the internal components (particularly the motor and gearbox), and the robustness of the software. Request mean time between failures (MTBF) data and seek out case studies or customer testimonials. A reliable vendor will be transparent about their product's performance and longevity, offering warranties and support plans that reflect confidence in their equipment.

Another crucial factor is ease of integration and support. The best screw locking system is ineffective if it cannot be easily integrated into your current workflow and machinery. Evaluate the vendor's ability to provide seamless integration services, including compatibility with your PLCs, robots, or MES systems. Furthermore, assess the vendor's post-sales support structure. Where is their technical support team located? What are their response times? Do they offer comprehensive training for your operators and maintenance staff? A vendor that provides strong local support and readily available spare parts can drastically reduce downtime and ensure continuous operation.

Finally, consider the total cost of ownership (TCO), not just the initial purchase price. This includes energy consumption, maintenance costs, the price of spare parts, and potential costs associated with downtime. A cheaper initial investment might lead to higher expenses in the long run due to frequent repairs and poor efficiency. A reputable vendor will help you understand the TCO of their equipment, demonstrating value through energy efficiency, low maintenance requirements, and high reliability that keeps your production line running smoothly.

In conclusion, selecting a vendor for screw locking equipment is a strategic decision. By thoroughly evaluating potential partners based on technical capability, build quality, integration support, and total cost of ownership, you can form a partnership that not only provides you with superior tools but also contributes to the long-term success and competitiveness of your manufacturing operations.