Industrial Automation Products Buying Guide: Top 6 Features to Consider

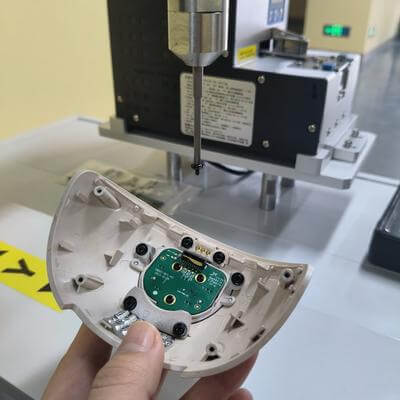

| Product Name | Applicable industries |

| CNC Screw Fastener | Automotive Electronics Assembly |

Top Features to Consider Before Buying Industrial Automation Products

Investing in industrial automation is a significant decision that can dramatically enhance your operational efficiency, product quality, and overall competitiveness. However, the vast array of products and technologies available can make the selection process complex. To ensure you make a sound investment that delivers long-term value, it is crucial to evaluate several key features before finalizing your purchase.

1. System Compatibility and Integration

One of the most critical factors is how seamlessly a new automation product will integrate with your existing machinery and control systems. Incompatible equipment can lead to costly delays, additional engineering hours, and suboptimal performance. Look for products that support widely adopted communication protocols such as EtherNet/IP, PROFINET, Modbus TCP, and OPC UA. A solution designed with open standards ensures smoother integration and future-proofs your investment, allowing for easier expansion down the line.

2. Scalability and Future-Proofing

Your operational needs will evolve over time. Therefore, the automation solutions you choose today should be able to grow with your business. Scalability is a vital feature. Consider whether the product line offers a range of sizes, capacities, and functionalities. Can you easily add more modules or nodes? Is the software platform capable of handling increased data loads or additional features through updates? Investing in scalable technology protects you from obsolescence and provides a better return on investment.

3. Reliability and Durability

The industrial environment is often harsh, with exposure to extreme temperatures, dust, moisture, vibrations, and electromagnetic interference. The reliability and durability of your automation components are non-negotiable. Examine the product's construction quality, ingress protection (IP) ratings, and mean time between failures (MTBF) data. Products built with robust materials and designed to withstand rigorous conditions minimize unplanned downtime, which is one of the largest costs in manufacturing.

4. Ease of Use and Maintenance

Complex systems that are difficult to configure, program, and maintain can negate the benefits of automation. Prioritize products that feature intuitive user interfaces, clear documentation, and user-friendly programming tools. Additionally, consider the ease of maintenance. Are components easily accessible? Is diagnostic information readily available to quickly troubleshoot issues? Products designed for simplicity reduce training time for your staff and lower the total cost of ownership.

5. Cybersecurity Features

As industrial operations become more connected, the threat surface for cyberattacks expands dramatically. Cybersecurity can no longer be an afterthought. Before purchasing any automation product, investigate its built-in security features. Does it support user authentication, role-based access control, and audit trails? Are communications encrypted? Are there secure boot capabilities? Choosing products with a strong security foundation is essential to safeguarding your critical production data and intellectual property.

6. Technical Support and Service

The quality of the manufacturer's support can be as important as the product itself. Ensure that the supplier offers comprehensive technical support, readily available spare parts, and detailed training resources. Responsive and knowledgeable support can drastically reduce downtime in case of an issue and ensures you can maximize the productivity of your automation investment throughout its entire lifecycle.

Taking the time to thoroughly evaluate these features will guide you toward making an informed and strategic decision. The right industrial automation products should not only solve an immediate challenge but also provide a flexible, reliable, and secure foundation for your future growth and innovation.