Robotic Screw Driving in Developing Countries | Manufacturing Automation

Robotic Screw Driving in Developing Countries

The global manufacturing landscape is undergoing a profound transformation, driven by automation and smart technologies. While developed nations have rapidly integrated advanced robotic systems, developing countries are now positioned to harness these innovations to leapfrog traditional industrial challenges. Among these technologies, robotic screw driving systems stand out as a pivotal tool for enhancing production efficiency, improving product quality, and fostering economic growth in emerging markets.

Bridging the Skills and Productivity Gap

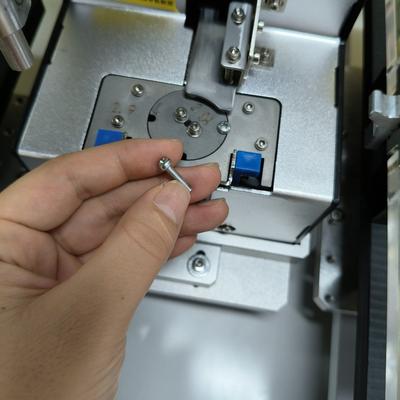

One of the most significant challenges faced by manufacturing sectors in developing nations is the shortage of highly skilled labor and inconsistent manual assembly quality. Repetitive tasks like screw driving are prone to human error, leading to product defects, rework, and increased costs. Robotic screw driving solutions offer a compelling answer to this problem. These systems deliver unwavering precision and repeatability, ensuring every screw is fastened to exact torque and depth specifications. This not only drastically reduces error rates but also minimizes waste and operational expenses, making local manufacturing more competitive on a global scale.

Economic Viability and Long-Term Growth

A common misconception is that automation is prohibitively expensive for growing economies. However, the modern landscape of industrial robotics tells a different story. Today's robotic screw driving systems are designed with affordability, scalability, and ease of use in mind. They represent a smart investment with a rapid return on investment (ROI) achieved through heightened productivity and reduced labor costs. For a developing economy, this means local factories can increase their output of high-quality goods, create more stable industrial job opportunities, and stimulate broader economic development by integrating into international supply chains.

Building a Foundation for Advanced Manufacturing

Adopting relatively simple automation technologies like robotic screw driving serves as a crucial first step toward broader technological adoption. It introduces workforce skills in programming, maintenance, and operation of robotic equipment, building a foundation for a more tech-savvy industrial base. This prepares the ground for the integration of more complex Industry 4.0 solutions in the future. Furthermore, as local industries become more reliable and efficient, they attract greater foreign investment and partnerships, creating a positive cycle of innovation and industrial advancement.

Key Benefits for Developing Markets

- Enhanced Quality Control: Automated systems ensure consistent product quality, which is essential for competing in export markets and building brand reputation.

- Increased Production Speed: Robots work tirelessly, significantly accelerating assembly lines and meeting demanding production schedules.

- Improved Worker Safety: By taking over ergonomically taxing repetitive tasks, automation reduces workplace injuries and allows the human workforce to focus on more value-added and supervisory roles.

- Operational Flexibility: Many modern systems are easy to reprogram and redeploy for different products, making them ideal for factories that handle diverse, low-volume, high-mix production runs.

The Path Forward

The integration of robotic screw driving technology is more than an upgrade; it is a strategic move toward sustainable industrial growth for developing countries. It empowers local manufacturers to overcome historical barriers of cost and quality, fostering an environment where innovation thrives. As these technologies become more accessible and user-friendly, they will undoubtedly play a central role in shaping the future of manufacturing in emerging economies, driving them toward greater prosperity and global competitiveness.

| Product Name | Applicable industries |

| Screw Fastening Unit | Smartphone Manufacturing |