Ensuring Longevity of Screw Locking Robot in Power Tool Assembly

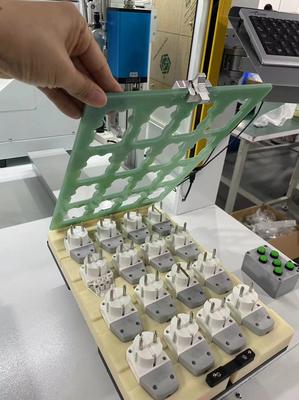

| Product Name | Applicable Industry |

| Automatic Screw Feeder | Power Tool Assembly Line |

Ensuring Longevity of Screw Locking Robot

In modern manufacturing, screw locking robots have become indispensable assets for assembly lines across industries. These precision-driven machines streamline production, minimize human error, and deliver consistent results. However, their operational lifespan directly impacts productivity and ROI. Implementing proactive maintenance strategies and optimizing usage conditions can significantly extend service life while maintaining peak performance.

Proper Installation & Calibration

A robot’s longevity begins with meticulous installation. Misalignment during mounting creates uneven stress on joints and motors, accelerating wear. Partner with certified technicians to ensure level installation on vibration-dampening surfaces. Post-installation calibration must align torque settings, screw feeding mechanism, and positional accuracy with application specifications. Re-calibrate quarterly or after significant component replacement.

Environmental Optimization

Contaminants pose the greatest threat to electromechanical systems. Install particulate filters on air supply lines and maintain ISO Class 8 cleanliness standards in work zones. Temperature fluctuations below 5°C or above 40°C degrade lubricants and strain servo motors. Humidity should remain stable between 30-60% RH to prevent condensation-induced corrosion while avoiding static buildup.

Predictive Maintenance Protocol

Transition from reactive repair to data-driven maintenance: monitor motor current draw spikes (indicating bearing wear), track torque consistency (±5% deviation threshold), and log pneumatic valve cycle counts. Use vibration analysis tools to detect early-stage gearbox imperfections. Schedule dielectric strength tests for wiring insulation annually.

Lubrication Management

Over-lubrication attracts debris; under-lubrication increases friction. Use automatic lubrication systems with programmable intervals matched to duty cycles. For high-speed applications (>15,000 RPM), employ synthetic grease rated for extreme pressure. Always purge old lubricant before replenishing to prevent additive breakdown contamination.

Component Upgrade Cycle

Proactively replace wear-prone parts: drive belts every 18-24 months, ball screws at 5-million-cycle intervals, and rotary unions after 12,000 operating hours. Upgrade legacy controllers to benefit from modern fault diagnostics and energy-saving algorithms. Retrofit older models with collision detection sensors to prevent overload damage.

Operator Training Essentials

Human error contributes to 23% of premature failures. Train technicians in proper emergency stop sequences, jam clearance protocols, and fastener compatibility checks. Implement shift-based inspections for end-effector alignment verification and feeder tube integrity assessments. Encourage reporting of minor anomalies before cascading failures occur.

Software & Firmware Updates

Manufacturers continuously optimize control algorithms. Install firmware updates to enhance motion path efficiency, reduce heat generation during rapid direction changes, and improve error code specificity. Maintain backup configurations to quickly restore settings after unexpected resets.

By integrating these strategies, facilities routinely achieve 12-15-year operational lifespans for screw-locking robots even in high-duty cycles. Remember—longevity isn’t about avoiding replacement, but maximizing value through every phase of the equipment lifecycle. Document maintenance history, analyze failure trends, and adapt practices as technology evolves. The result? Uninterrupted precision, reduced downtime costs, and sustained competitive advantage in automated manufacturing.