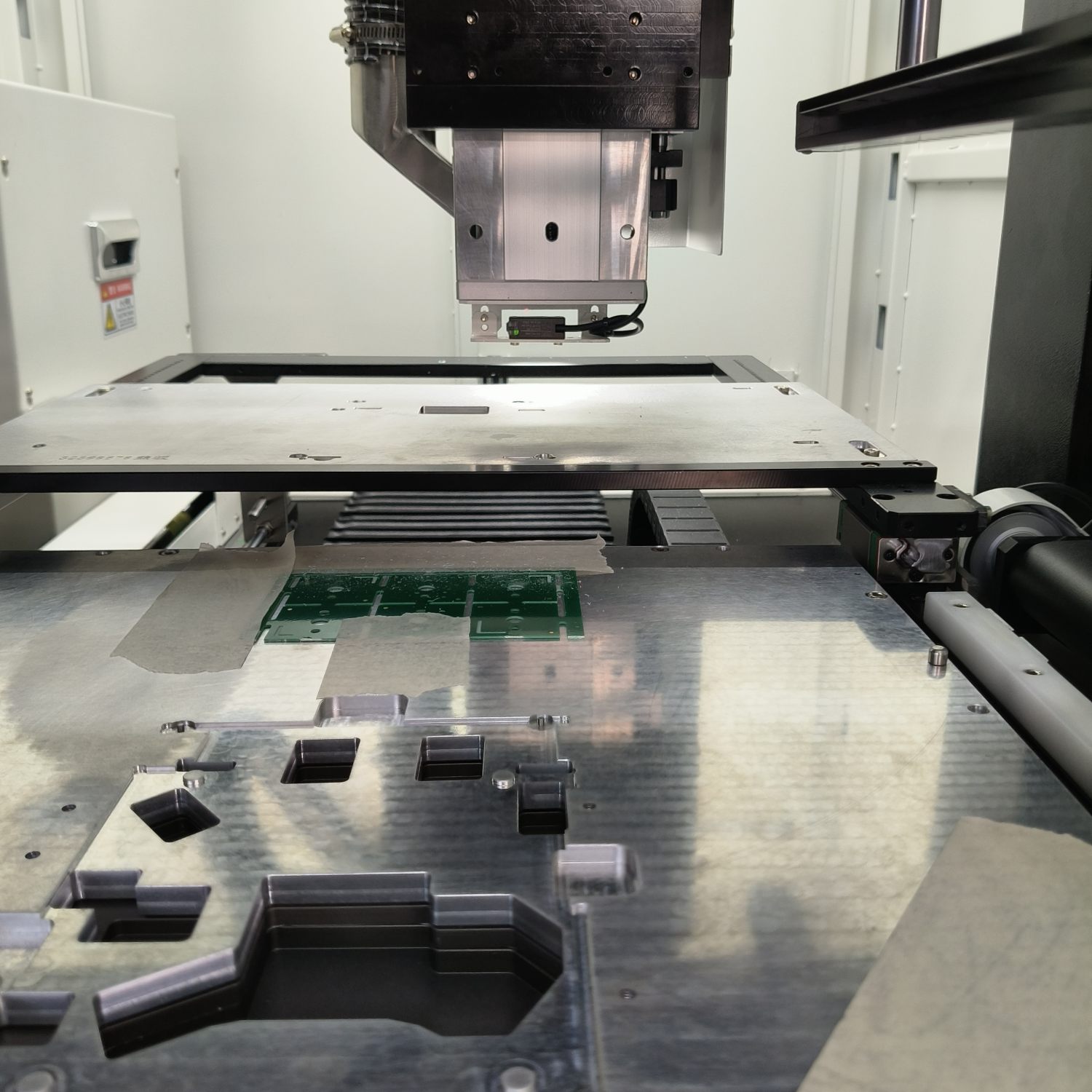

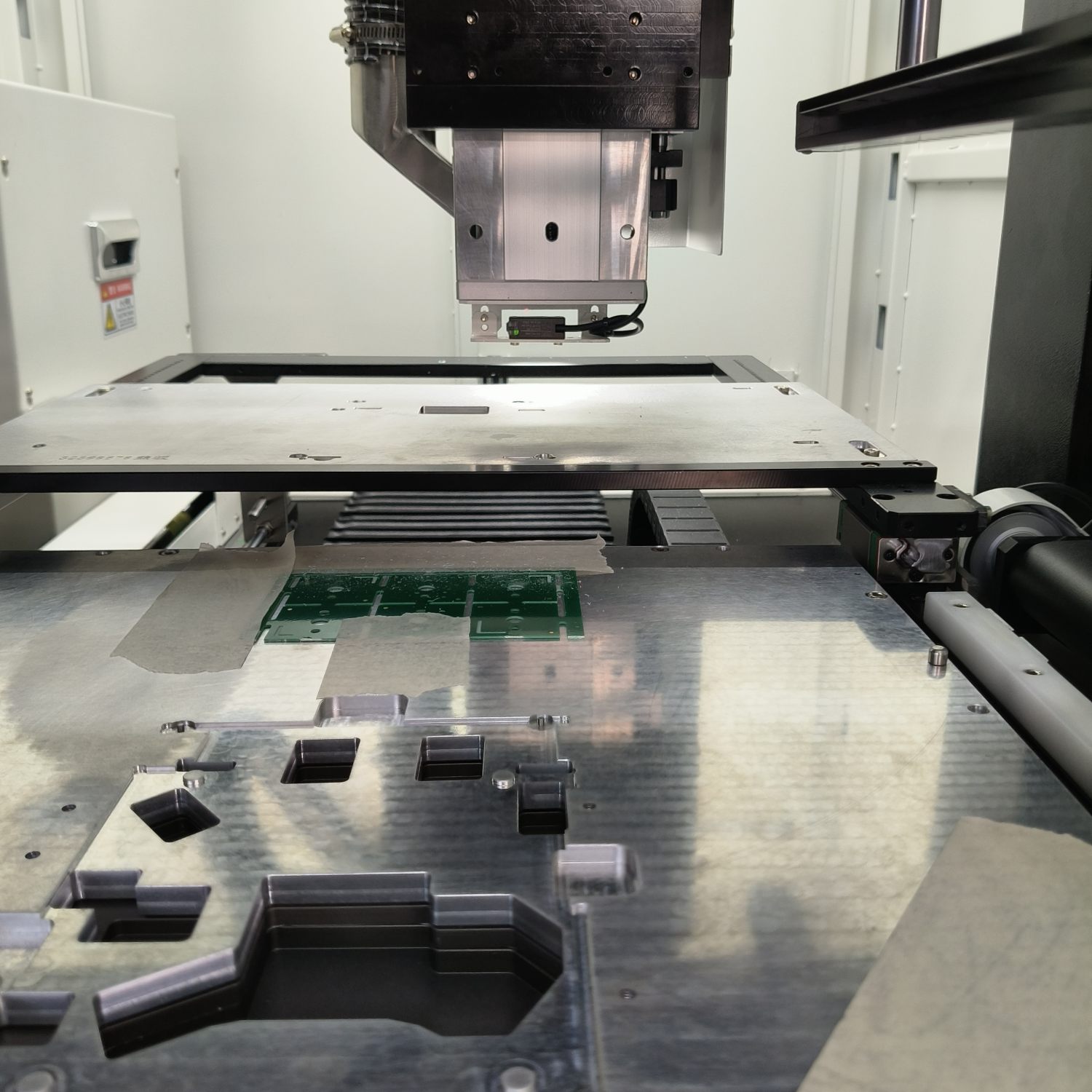

1. All the moving axes of this equipment adopt high-precision modules, which are high-precision and beautiful. 2. The automatic board separation mechanism adopts a precision module equipped with a high-definition CCD module, which has a dust suction function. It is equipped with a broken knife detection function as standard, and can be upgraded to an automatic knife change function. 3. The loading and unloading mechanism of the manipulator adopts a vacuum adsorption method, and is equipped with a high-vacuum combined vacuum component and a suction cup quick adjustment structure. It has strong versatility, is easy to adjust, and is more convenient to replace products.

| Category | Item | Specification | |

| Identification system | Automatic Mark Point Search Function | Color image search and positioning | |

| camera | 500W color CCD camera | ||

| Image processing speed | Image processing time <300MS/FOV | ||

| Anti-static measures | Static eliminator, anti-static fixture, anti-static socket | ||

| Processable PCB size (MAX) | L330*W260mm | ||

| Cutting accuracy | ±0.01mm (actually considering product and fixture tolerance) | ||

| Processable PCB thickness | 0.5mm-3.0mm | ||

| Mechanical system | X, Y, Z Platform |

Drive equipment | Precision five-axis servo motor + 1-axis closed-loop stepper motor system/precision guide rail, precision ball screw |

| Imported spindle speed | High speed electric spindle (20000-80000) RPM | ||

| Broken tool detection | Standard configuration | ||

| Spindle brand | Germany SycoTec (KAVO) | ||

| Servo motor | Panasonic | ||

| Linear guide | Hiwin | ||

| Ball screw | TBI | ||

| Machine repeatability | ±0.01mm | ||

| maximum movement speed | X-axis: 610 mm/s; Z-axis: 100 mm/s | ||

| Software system | Operating system | Windows10 | |

| Equipment testing | Automatic detection function at startup | ||

| AutoCut Program Features | 1.Data can be processed through CCD learning; 2.Optional DXF import processing function and whole board scanning function; |

||

| Control system | Computer host | professional computer | |

| Display screen output | 19.5′ LCD Monitor | ||

| Other parameters | Equipment weight | About 700KG | |

| Power supply | Host: Voltage AC110/220V 2phase 50/60HZ Dust collector: Voltage AC380V 3phase 50HZ. 5P |

||

| Air supply | 4-6kg/cm² | ||

| Vacuuming method | Bottom vacuuming/top vacuuming optional | ||

| Overall machine dimensions | L1214*W1280*H1605mm (excluding warning light height) | ||

| Noise | 75db±5dB (1 meter away from the equipment) | ||

| Vacuum cleaner detection method | Pressure detection (lower vacuum cleaner has suction alarm function) | ||

Product Description

Windows operating system

*Windows 10 operating system

*Stable&safe

*Easy to learn and use

Customer case

Package